JSW M&E provides the inspection work for petroleum refineries and chemical plants, based on general non-destructive examination methods and originally developed inspection technology.

JSW M&E provides the high quality inspection services in short time by using the above inspection technologies.

| Inspection Technique | Typical inspection application area |

|---|---|

| Manual UT | Weld joint, Weld overlay Disbonding |

| Time Of Flight Diffraction (TOFD)-UT | Weld seams |

| Magnetic particle exam. (MT) / Liquid penetrant exam. (PT) |

Weld seams, Weld overlay |

| Widespread Array UT (Flat Array UT) * |

Weld overlay Disbonding |

| Boiler tube inspection system * | Thickness measurement for Boiler tube |

| High speed inspection system for heat exchanger tube (HI-UT) * | Thickness measurement for heat exchanger tube |

| Thickness measurement system for storage tank (T-RIS / G-RIS) * |

Thickness measurement of plates for oil storage tank |

| Thickness measurement system for 3D surface (Flex-Array UT) * |

Thickness measurement for piping, elbow, etc. |

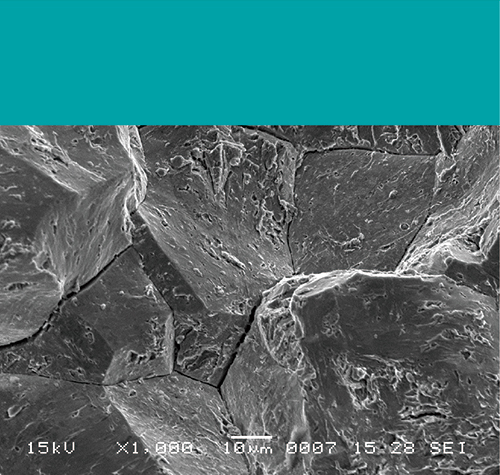

| Replication, Hardness measurement, Positive Material Identification (PMI), Ferrite measurement |

Basemetal, Weld seam, Weld overlay |

JSW M&E will consider and customize various other inspections as well.

*mark : JSW M&E’s original inspection technology.